Design of engineering systems: stages and key aspects

Well-thought-out engineering systems are the foundation of comfort, energy efficiency and safety of any building. The quality of the project determines whether heating, ventilation, electricity and water supply can operate smoothly and without overspending resources. At the start, it is important to assess not only the cost of installation, but also the prospects for modernization: for example, find out how much turnkey solar panel installation price will cost if you decide to integrate renewable sources in the future. Below are the key stages of engineering systems design and the factors affecting successful implementation.

1. Collection of initial data

The first step is a thorough audit of the facility. Engineers study architectural drawings, site geology, climate indicators and regulatory restrictions. A list of heat, cold, water and electricity consumers is compiled, and the level of automation and redundancy is determined.

2. Technical assignment (TA)

Based on the collected data, a TA is compiled, which records the required temperatures, design loads, permissible noise levels, backup power supply schemes and energy efficiency requirements. The document is agreed upon with the customer and the architect, setting the vector for the entire subsequent project.

3. Conceptual solution

The engineer creates several options for schemes: for example, a classic gas boiler house or a hybrid "heat pump + solar collectors". Capital and operating costs are estimated, a comparative table is prepared. The selected concept is approved by the technical council.

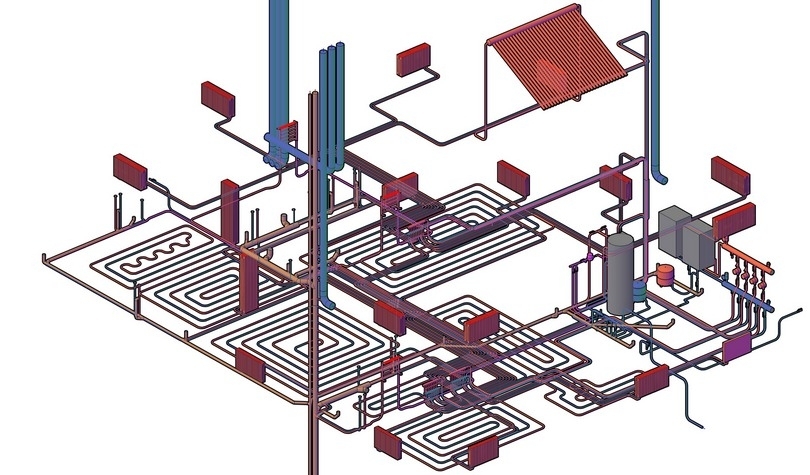

4. Preliminary (sketch) design

Heat supply, ventilation, power supply and water supply schemes with the arrangement of the main equipment are developed. Thermal and hydraulic calculations are carried out, pipe diameters, cable cross-sections, pump and fan capacities are selected. The sketch helps to identify collisions with architecture and structures at an early stage.

5. Working documentation

At this stage, engineers prepare detailed drawings-plans, equipment specifications, cable and pipeline logs, automation schemes. The documentation is transferred to the installation organization and serves as the basis for forming an estimate and work schedule.

6. Coordination and examination

The project is transferred to external authorities: energy companies, water utility, construction control authorities. If necessary, smoke removal, acoustics and energy efficiency calculations are carried out to obtain permits and pass the state examination.

7. Author's supervision

During construction, the designer monitors the compliance of the installation with the working drawings, promptly adjusts solutions when hidden design features are detected, and participates in acceptance testing of the systems.

Key aspects of a successful project

- Integration of the BIM model to eliminate intersections of communications before entering the site.

- Use of energy-saving equipment of class A+++ and control systems based on presence sensors and weather curves.

- Redundancy of critical components (pumps, UPS, heat sources) for increased reliability.

- Possibility of scaling: laying cable channels and free slots in panels for the future connection of new consumers.

- Reduction of operating costs due to the use of low-maintenance materials — PEX pipes, silent EC fans, LED lighting.

Typical mistakes and how to avoid them

Problems often arise due to incomplete technical specifications, when new customer requests appear during construction. The solution is a detailed interview and recording all requirements on paper. Another common mistake is the lack of coordination between the HVAC, VK and EOM sections, which leads to collisions. Using a single BIM environment and regular meetings of multidisciplinary teams minimize this risk.

High-quality design of engineering systems is the result of a systematic approach: from competent collection of initial data to author's supervision. Investments in a professional project pay off many times over: energy efficiency increases, construction times are reduced and operating costs are reduced. When planning a new facility or renovation, choose a contractor who offers a range of services and takes into account the prospect of introducing renewable technologies - this way your project will remain relevant for decades to come.