Turnkey electrical wiring in the house: stages of work and deadlines

New electrical wiring guarantees safety, energy efficiency and ease of control of household appliances. To get a predictable result, owners of private cottages increasingly trust the comprehensive service Electrical installation work for a private house, in which the contractor takes on all tasks - from calculations to commissioning. Let's consider how each stage goes and how many days it will take before the last circuit breaker is turned on.

1. Design (3-7 days)

The electrical project reflects the distribution of loads, power and low-current lines, group circuit breaker diagrams, calculation of cable cross-section and connection points. The engineer lays down a 20-25% reserve in power, takes into account the number of floors and the prospect of connecting renewable energy sources. Coordination of drawings and specifications of materials usually takes a week.

2. Preparatory dismantling (1-2 days)

If the house is being reconstructed, old aluminum wires and obsolete machines are dismantled. During a complete overhaul, wooden cable channels, corrugated pipes and distribution boxes are removed; openings are sealed with non-flammable compounds.

3. Marking routes and chasing (2-4 days)

The craftsmen apply horizontal lines with a laser level along a line 30 cm from the floor and 15 cm from the ceiling, mark verticals to sockets and switches. After agreeing on the height of the points (the standard is 90 cm for sockets and 100-110 cm for switches), chasing of the walls is performed. In brick and aerated concrete it goes faster, in monolithic concrete diamond cutting and dust removal are required.

4. Laying cable lines (2-3 days)

For the power network, use copper VVGng-LS 3x2.5 mm2 for socket groups and 3x4-6 mm2 for powerful loads (electric stove, boiler, EV charging station). For lighting - 3x1.5 mm2. The cable is laid in a PVC corrugated pipe or soundproof pipes, fixed with clips every 40-50 cm. Low-current lines (Internet, alarm) go in separate grooves at intervals of at least 20 cm from the power lines.

5. Installation of wall boxes and distribution boxes (1-2 days)

The wall boxes are aligned along a single axis with a tolerance of +/- 1 mm — this determines the aesthetics of the future frame block. We recommend non-flammable plastic models with a depth of 60 mm: it is more convenient to make WAGO connections in them.

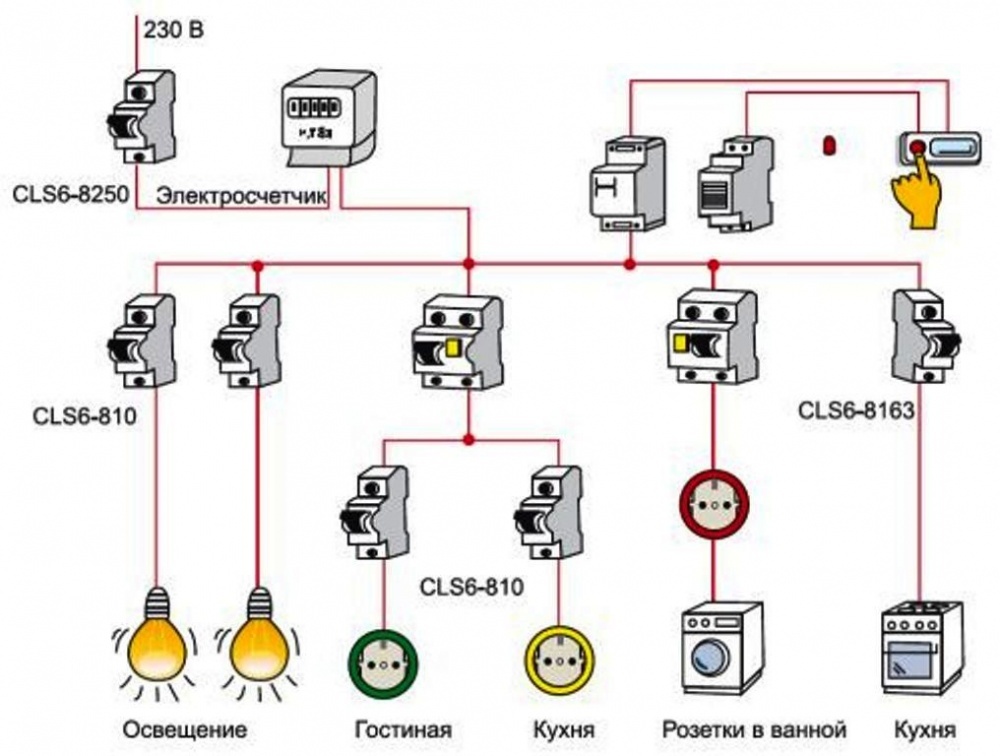

6. Assembly and installation of the electrical panel (1 day in the workshop + 1 day on site)

The electrical panel is assembled on DIN rails: input circuit breaker, RCD/RCD circuit breakers by groups, voltage control relays, contactors and a surge protection device. The PE/N busbar is marked with color, the conductors are signed. Factory crimping of the tips reduces the connection time on site to several hours.

7. Plastering, finishing and fittings installation (after the walls have dried, 2-3 days)

After checking the insulation and test run, the route is plastered. After 5-7 days, sockets, switches, Ethernet sockets and antenna terminals are installed. Fittings are mounted without skewing, tightening force - until the plastic stops in the socket box.

8. Final testing and commissioning of the facility (1 day)

The engineer takes readings from the megohmmeter, checks the integrity of the grounding circuit, signs the act of hidden works. The client receives an electrical installation passport and a wiring diagram for future maintenance.

Total duration

| Stage | Minimum | Maximum |

|---|---|---|

| Project and estimate | 3 days | 7 days |

| Dismantling | 1 | 2 |

| Chasing | 2 | 4 |

| Cable laying | 2 | 3 |

| Socket boxes, boxes | 1 | 2 |

| Panel and connection | 2 | 2 |

| Finished finishing | 2 | 3 |

| Tests and delivery | 1 | 1 |

| Total | 14 days | 24 days |

Factors affecting the timing

- Area and number of floors: house 150 m² is installed faster than a 400 m2 mansion.

- Wall material: chasing aerated concrete is twice as fast as reinforced concrete.

- Complexity of smart home scenarios and the presence of a generator or solar station.

- Seasonality: in winter, the drying time of the plaster increases by 1-2 days.

Tips for optimizing time and budget

Order a full set of cables and automation before the start of the work work — avoid downtime. Agree on frame colors and hardware brands in advance: replacing a position in the middle of a project will delay delivery. If a temporary electrical circuit is needed for living, provide a separate input with a 16 A residual current circuit breaker and a portable panel.

Turnkey electrical wiring frees the customer from dozens of approvals and risks. A clear schedule, factory assembly of the panel and professional equipment allow you to complete the work in two to three weeks, even with a complex home configuration. An experienced team will provide a guarantee of up to 5 years and provide service without hidden payments. An application for calculation takes five minutes, and a reliable power supply will serve for decades.